Harnessing gravity

LiquiPrep variant uses gravity for high-viscosity materials

The higher the viscosity of a material, the greater the demands it places on its preparation and feeding in dispensing systems. But the trend right now is to u...

|

Dispensing |

The DosP DP2001 piston dispenser provides a solution for the industry requirements of Automotive Electronics, Industrial Electronics, Medical Electronics and Consumer Electronics for the shortest cycle times and highest dispensing qualities. It also covers a wide range of materials: In addition t...

|

Dispensing |

Rugged, fast and consistent – even with high inlet pressures

Dos GP systems are the first choice for applications requiring 1C, high viscosity, unfilled, non-abrasive potting material, making them the best choice for applying continuous beads. The dispensing ...

|

Dispensing |

The Allround Solution for Low Volume Applications

Whether bonding, sealing, filling or heat dispensing, their simple, robust design makes piston dispensers the systems of choice for many different tasks. They also cover a wide range of materials: In addition to very liqui...

|

Dispensing |

Ultimate performance with a small footprint

Multi-piston dispensers are used for the output of large batch quantities and for short cycle times. These systems can pot several workpieces in a single potting cycle. They are particularly suited for potting a large number ...

|

Dispensing |

Scale UP your performance!

The DispensingCell DC803 is a new high-performance multifunction cell for demanding dispensing applications. The cell was specially designed for series production with short cycle times and high volumes. ...

|

Dispensing |

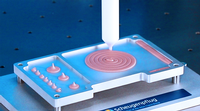

Pump UP your material quality!

There’s no denying it: Electronic components have to work. An optimal dispensing performance as well as an absolutely homogeneous and bubble-free material are the prerequisites for this. The new LiquiPrep LP804 system incorporat...

|

Dispensing |

For highly viscous, abrasive, and filled materials in straight walled 5 gallon buckets or 20l pails. Coupled with our special TCA metering head is designed for thixotropic Thermally Conductive Materials with higher viscosities. Low system and operating pressures improves operational s...

|

Dispensing |

Up to 90 Percent Less Material Waste per Cartridge Change

Scheugenpflug has further developed the proven material feeding unit for dispensing applications with high viscosity materials and low media consumption: The new A90 CV not only ensures a process reliable a...

|

Dispensing |

The system includes a 3-axis-system and a light curtain as well as the proven Dos P016 and the cartridge expulsion unit A90 C with filling level monitoring.

Advantages

Fast start of production

Unrivaled service life

Short deliv...

|

Dispensing |

The Dos P016 / 050 / 100 / 300 / TCA piston dispensers are high-precision volumetric dispensers designed to process 1C and 2C materials and cover a wide range of applications. Precisely dimensioned dispensing cylinders provide the ability to obtain reproducible material volumes. When 2C mat...

|

Dispensing |

Compact and optimized for simple adhesive bonding and potting tasks

The DesktopCell is a compact system solution for small to medium-sized batches and for prototype production. It combines all the advantages of a fully fledged dispensing cell with a small footprint. No...

|

Dispensing |

Focusing on small and medium-sized batch production -

The LeanCNCell is specially designed to handle dispensing and potting of small to medium-sized batches. It combines all the advantages of the CNC system plus a high-precision axis controller with attractive performa...

|

Dispensing |