With Pressurex®, variations in pressure that can lead to defects are easily detected and corrected—decreasing scrap, improving yield, and increasing productivity.

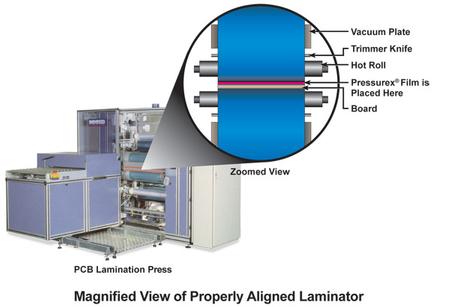

Even, consistent bonding of the thin layer of photoresist is critical to the board’s subsequent electrical performance. The photoresist material is placed on the board’s surface using a hot roller system. If the rollers do not exert uniform pressure across the board’s surface, the thin photoresist layer can fail to adhere, bubble or even wrinkle during the process. This causes electrical instability and possible failure of the resulting board.

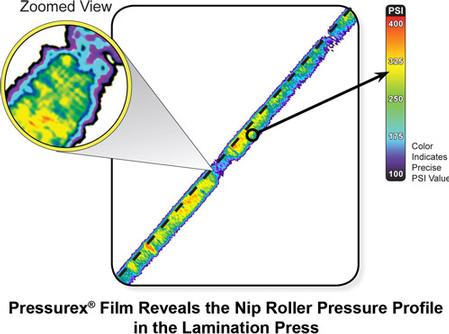

Pressurex® reduces lamination defects by ensuring alignment and parallelism of the rollers. The film is placed between two rollers before closing the nip and applying pressure. I nstantly a pseudo color map of pressure magnitude and distribution is revealed. The precise pressure magnitude is easily determined by comparing color variation results to a color correlation chart (conceptually similar to interpreting Litmus paper).

Pressurex® is virtually indispensable for manufacturing process control and machine/component inspection. The pressure-indicating film is very thin (4 mil or 8 mil thick) and can be hand- or laser-cut to any size or dimension. It is flexible and conforms to curved surfaces and tight spaces.

Pressurex® measures pressure from 2 - 43,200 PSI (0.14 - 3,000 kg/cm2). For a free sample, contact Sensor Products Inc. at 1.973.884.1755 (USA), email info@sensorprod.com or visit their website at http://www.sensorprod.com/sample where you can view their entire line of products.

-END-

About Sensor Products Inc. (USA)

Headquartered in New Jersey and established in 1990, Sensor Products Inc. is a world leader in the manufacture and distribution of tactile pressure sensing solutions. Their customized and off-the-shelf products are installed within all of the Fortune 500 industrial companies as well as thousands of smaller manufacturing firms. Their sensors are used in applications as diverse as tire testing to semiconductor manufacturing and from R&D labs to space missions. Additionally, Sensor Products provides in-house and on-site stress and pressure mapping analysis, as well as a variety of regional technical seminars.