Sono-Tek Corporation (OTC BB: SOTK), a worldwide precision ultrasonic coating equipment manufacturer, will demonstrate the SonoFlux Servo WS Ultrasonic Spray Fluxing System in Booth #3700 at the upcoming IPC APEX Expo, scheduled to take place February 28 - March 1, 2012 at the San Diego Convention Center in California.

The SonoFlux Servo WS is a fully automated reciprocating ultrasonic spray fluxing system that is designed for spraying water soluble/organic acid fluxes. All of the wetted materials, including the pumping system, liquid lines, fittings and ultrasonic spray nozzle, are constructed with materials that are proven compatible with these very corrosive fluxes. The SonoFlux Servo WS incorporates Sono-Tek's non-clogging ultrasonic spray nozzle with high Impact controlled velocity air shaping technology for excellent through-hole penetration without overspray.

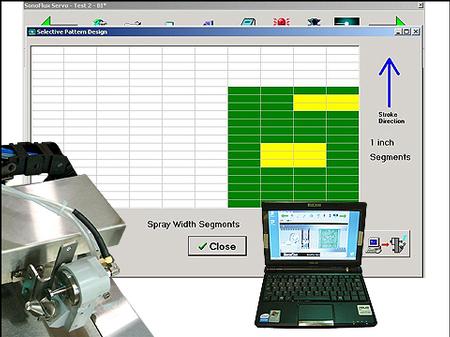

The SonoFlux Servo WS allows selective fluxing of pallets or full area coverage with user-friendly programming and recipe storage controlled via a compact notebook using Windows®-based software. This versatile system is easily integrated with all major wave solder machines. The flexibility of selective area fluxing or full board width coverage combined with the ability to spray aggressive high solids fluxes without clogging makes the SonoFlux Servo WS an important tool for PCB manufacturers worldwide.

Sono-Tek Corporation is one of the originators of ultrasonic spray fluxing technology and continues to be the industry's leader in ultrasonic spray fluxing systems, with a full line of spray fluxing systems to suit any PCB manufacturer's needs. For more information, visit www.SprayFluxing.com or http://www.sono-tek.com/electronics/page/sonoflux_servo, or email info@sono-tek.com.

To view a video of the SonoFlux Servo WS in action, visit http://www.youtube.com/watch?v=T4FaT6aits0&list=UUsjBhCR_QQaYdmq2OuHkKAQ&index=34&feature=plcp.

Sono-Tek is the world leader in the development and application of liquid ultrasonic atomization technology into nozzle systems and spraying and coating application systems. Compared to conventional pressure spraying methods, the company’s ultrasonic nozzles do not clog, reduce liquid usage, waste, and environmental impact while achieving much more precise, uniform, thin film coatings. Sono-Tek is continually developing new applications for its unique technology, replacing wasteful practices in a world that is growing ever more environmentally sensitive.