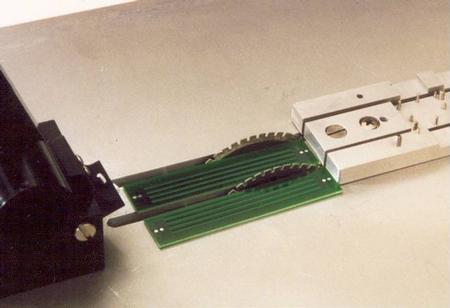

For high precision low stress PCB singulation of PCBs with sensitive components near the parting edge, and with the smooth edge finish required by military specifications or by packaging considerations, using a Diamond Blade Saw beats routing for speed and for blade life. The saw blade, a 2.95" (75mm) diameter .021" thick diamond coated cutting disk, provides a low-stress, ultra smooth edge finish for separting panelized Printed Circuit Cards.

Now available from FKN Systek, the S300 multiple blade depaneling saw for use in singulating assembled PCBs. The S300 is a PLC controlled machine which can singulate up to 24 lines in one pass. The operator places the board to be cut onto the tooling plate and a hold down lid is placed on top of the panel. STI safety sensors are built into the lid so operation will automatically cease if the lid is opened during the process.

Built in dust extraction vacuum and and external dust extraction line is provided for dust removal during the process and for board clean up after the singulation process is finished.

Made to provide a stress free method to singulate panels with sensitive surface mount components close to the edge of the parting section, the FKN systek diamond blade depaneling saws leave a smooth edge finish with minimal stress imparted to the PCB. The saws can also be used to singulate PCBs without scorelines, or to singulate PCBs with overhanging components on the parting line. Since the cutting depth can be set to just cut through the PCB itself, any components which overhang the parting line will remain intact.

»

»