Wednesday, October 21, 2015

News Equipment Installation

BEST Increases Products Capacity and Capabilities with New YAG Laser System

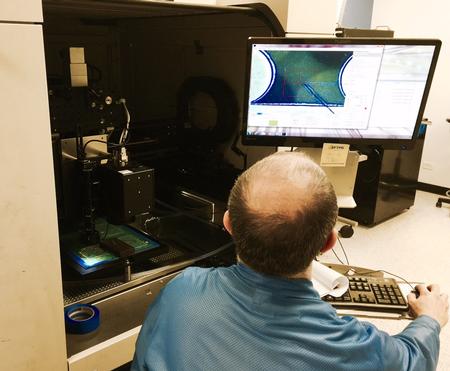

Rolling Meadows, IL – Rolling Meadows, IL – BEST, Inc., a leader in the development and instruction of PCB rework and repair processes and tools, announces the installation of a new customized laser system that will allow it to bring down product lead times while increasing production capacity. This is BESTs’ 5th laser system and features advanced step and repeat software, electronic precision focal alignment as well as large micro motor driven precision x-y alignment system. This system was specified by BEST and built by a custom machine builder per BESTs’ unique requirements.

Dan Patten from BEST Inc. reported “We are excited about being able to bring down lead times of rework and repair products while being able to do more sophisticated selective mask ablation, flex circuit cutting and other precision micro machining for the electronics industry.”

BEST’s manufactures a line up of unique rework and repair products on lasers such as these including the EZReball™ reballing preform, the StikNPeel™ plastic film stencil, circuit frames for PCB repair and several others.

In addition to reducing the production lead time of its products BEST can offer board shops , OEM and contract assemblers laser machining services including coverlay and flex machining, board de-panelizing, laser hole drilling, part marking and coating removal amongst other applications.

About Business Electronics Soldering Technologies (BEST)

Headquartered in Rolling Meadows, Illinois BEST is a supplier of PCB rework and repair services as well as tools for those services in the communications, computer, industrial, automotive, avionic and military sectors. In addition BEST is a master IPC-certified training center certifying students and instructors in J-STD-001, IPC-610 and IPC 7711 and 7721 material.

Contact: Bob Wettermann

BEST Inc.

(847)-797-9250

www.solder.net