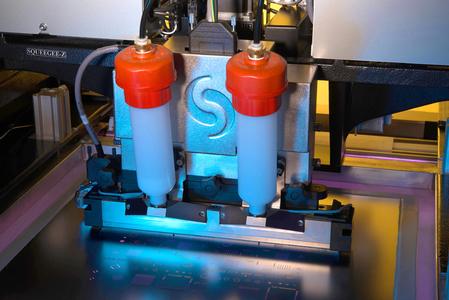

The MPM® EnclosedFlow™ print head by Speedline Technologies is a revolutionary enclosed media printing technology that offers significant process and cost advantages over printing with metal squeegee blades. Solder paste is held within an enclosed chamber, and is directly pressurized during the print stroke to provide uniform and complete aperture filling for the full range of aperture sizes and fill types.

EnclosedFlow features an all new positive-displacement, motor-driven pressure system that controls paste chamber pressures to within +/- 0.1 psi, setting a new standard for tight process control, and delivering superior volume/yield on fine pitch pads. Print fine features such as 01005s and 0.3mm pitch CSPs with up to 50% greater volume and 25% lower deviation than squeegee blades. EnclosedFlow is also superb for high-volume fills such as paste-in-hole, where complete barrel filling is desired.

EnclosedFlow is MPM’s ‘plug-and-print’ solution, because it’s easy to set up and operate, providing superior results from the first print. It recovers instantly from production pauses, and generates paste savings in many cases in excess of 50% for a fast payback. With fewer parts, EnclosedFlow is quicker and easier to clean, with less paste waste, and changeover to a different head or from a blade setup is accomplished in only a few minutes.

EnclosedFlow is perfect for high product mix environments, since its easily detachable, modular chambers (different paste types, Pb-free, Sn/Pb) can be removed and safely stored with less than 5 minutes needed for changeover. No need to throw away paste at the end of a shift; save 100s of grams of paste each day by simply removing and storing the print head for the next time it’s needed. EnclosedFlow also uses industry-standard cartridges.

EnclosedFlow is available for the MPM Momentum series, Accela, and new printers; supported sizes include 8”, 10”, 12”, 14”, 16” 18” (203mm, 254mm, 305mm, 356mm, 406mm, 457mm).

Speedline Technologies is the global leader in process knowledge, services and manufacture of capital equipment used in the printed circuit board assembly and semiconductor industries. Based in Franklin, Massachusetts, USA, the company markets five best-in-class brands: Accel microelectronics cleaning equipment; Camalot dispensing systems; Electrovert wave soldering, reflow soldering and cleaning equipment; MPM stencil and screen printing systems; and Protect global services, support and training solutions. For more information about Speedline Technologies visit www.speedlinetech.com