SIPLACE technology expert Norbert Heilmann is thrilled: "Our close and successful cooperation with Intel makes the BGA programming process definitely a lot easier and faster for our customers, because SIPLACE placement machines can now import the design data of the irregular Intel BGAs directly." Irregular BGA components have balls that are distributed over their surface at irregular pitches. In many instances, these variations are as small as a few µm. A wizard that interprets an image of such a BGA to define these pitch distances is not always correct when the pitch differences are so small. That is why in the past these components often had to be programmed individually and sometimes even described down to the individual ball level. This was the only way to make sure that each individual ball position (of up to several thousand) was accurately described – a very time-consuming and complex process.

Hence, SIPLACE and Intel decided to take advantage of the fact that the design data of these components is available at a very early stage in the development process.

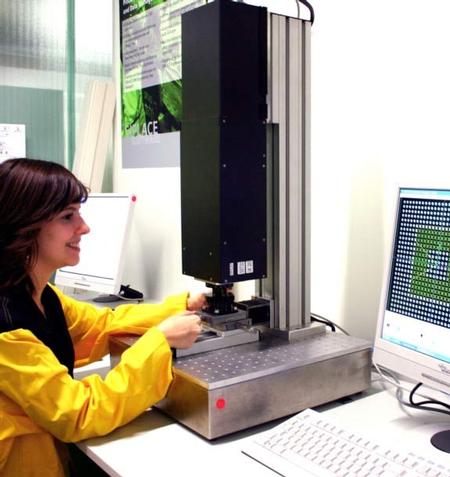

Together with the Intel’s Customer Manufacturing Enabling team around Todd Harris, the SIPLACE experts developed a function for the SIPLACE Vision Teach Station that imports the design data and the X/Y coordinates for each ball directly into the SIPLACE Pro programming system. This prevents transcription errors and significantly speeds up the time required to describe irregular BGAs. As a result, the whole line becomes a lot more productive – especially for new product introductions.

For interested and registered SIPLACE customers the SIPLACE team offers the short manual "SIPLACE Vision System – Easy data import of irregular BGA balls" for download on the SIPLACE website, with the keyword ‘Insights BGA’ at: http://www.siplace.com