DIGITALTEST EXHIBITION NEWS (Hall A1, Booth 365)

The Condor, MTS 505 is the latest generation of flying probe test system from Digitaltest. The system now provides support for larger and heavier boards. When combined with our latest measurement hardware it can provide even higher test coverage while keeping maintenance requirements extremely low. With new sophisticated software, new hardware innovations, comprehensive boundary scan integrations (JTAG Technologies/Göpel Electronic) and new flying and opens check probes, the new Condor MTS 505 is equipped for the future of fixtureless testing.

Condor users can now probe the smallest components using the innovative technology of the new flying probe which allows closer probe distances. This in turn allows for even greater test coverage with more accurate probing.

All Condor users can profit from the probe upgrade package to enjoy the benefits of the new flying probe and opens check probes.

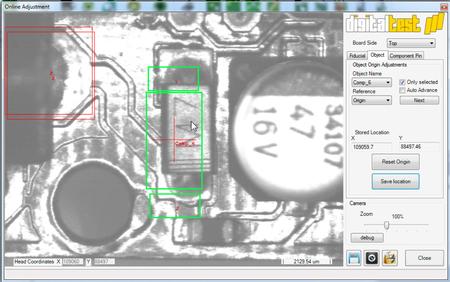

Digitizer 2.0 is here - Recovery of CAD-Designs

The next generation of the Digitizer has been developed as part of the research project INPIKO, and can do more than re-generate Netlists. Now it is possible to import and use data and CAD data from any preceding processes. Together with a Condor flying probe test system this enables highly automated recovery of the CAD-Design.

In addition Digitizer 2.0 provides new methods for the determination of unknown component values using true metrological techniques.

Next round of the CITE test system software

CITE 7 is the new test system software from Digitaltest. It’s open architecture can meet all the future requirements in a Visual Basic .NET stand-alone world and is compatible with Windows 7 (32/64-bit).

In the new CITE 7 software the user can switch between VB or, NET based code and the user-friendly, GenFast tabular format. All existing test programs can also be seamlessly integrated into CITE 7.

FORUM & ACTION DAY

INPIKO research project:

In the Speakers Corner, Erik Horn, from Digitaltest will give a presentation titled: “Obsolescence Management: Recovering CAD Data from Assembled Circuit Boards“. Following this presentation all interested visitors are cordially invited to the Digitaltest booth (Hall A1, Booth 365). Here the project participants from the involved companies will be available for questions and discussion.

The INPIKO research project – Integrated Process Chain for Maintenance of Electronic Components – was supported by the BMWi and the ZIM funding program.

DIGITALTEST TEST SYSTEMS

19” Rack/Bench Tester Sparrow MTS 30

This space-saving, flexible all-rounder can be used as a bench top tester or simply fitted in any 19” rack. Various Sparrow inline integrations can be seen at the booths of our partners 6TL Engineering (Hall A1, Booth 151) and JOT Automation Ltd. (Hall A3, Booth 415).

Pneumatic Press Tester Eagle MTS 180

Providing the lowest fixturing cost, the MTS 180 “bed of nails” tester enables efficient testing of large quantities, even using complex fixtures. The pneumatic press also allows two-sided testing.

In-Circuit-Tester Sigma MTS 300

The Sigma MTS 300 with its vacuum interface, has up to 3,456 test pins is an extremely high-performance system. This test system was developed for large-scale production, and its speed of up to 1,000 measurements per second makes it one of the fastest test system on the market.

DIGITALTEST TOOLS & SOFTWARE

FailSim – automatic checking of test programs

The new “FailSim” tool allows you to detect and prevent wrong component measurements in analogue in-circuit testing. This ensures higher measurement quality, since the user is directly assisted in the debugging process.

C-LINK DTM (Design To Manufacturing) – the CAD/CAM software

C-LINK is a CAD/CAM software which imports and processes the CAD data from assembly layouts, bills of material and circuit diagrams. It thereby controls the translation of the design data from the CAD system to any desired test system. The software also creates analyses for accessibility and testability for development as well as production release. With a variety of outputs for fixture construction, in-circuit testing, flying probe test systems, boundary scan and AOI, C-LINK is a universal tool which lowers testing costs and the introduction time for new products while improving quality.

QMAN (Quality Management Solutions)

QMAN is the quality management software for all back-end test and inspection processes including: Digitaltest testers as well as those from other companies. It makes all data from test and inspection instantly visible, speeds up repairs while, monitoring and evaluating the production process. Real-time production data is made available to all stations over the network, Based on the verified repair data any possible defect trends can be detected and statistical reports generated to make production quality transparent. QMAN also features an intelligent repair database with repair guides – for greater efficiency in the production process and higher product quality.

Headquartered in Stutensee, Digitaltest GmbH is a global provider of a wide range of products for electronic testing of printed circuit boards along with comprehensive software tools. The company’s leadership is evidenced by more than 2,000 installations for leading companies in electronic manufacturing services (EMS), the automobile industry and in transportation, aerospace, in telecommunications, medical and industrial technology as well as consumer electronics. www.digitaltest.com.