Digitaltest preview for Aerospace Electrical Systems Expo Bremen, November 17th to 19th, Booth # F85

This year Digitaltest celebrates their 35th anniversary

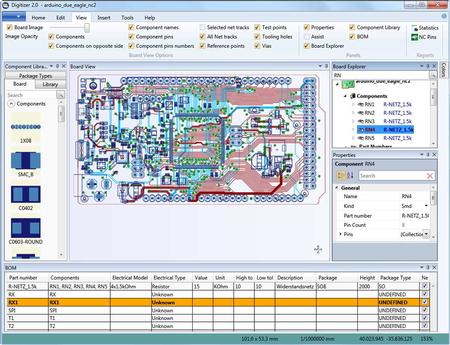

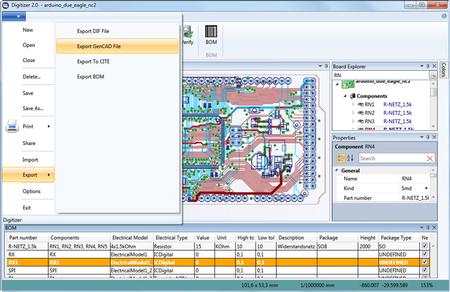

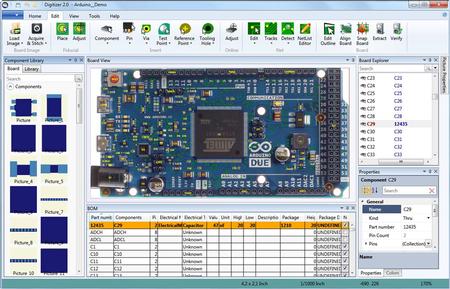

Digitaltest is presenting its newest innovative Digitizer 2.0 software that can recover lost CAD design data of electronic components.

With the growing challenges of maintenance, repair and overhaul (MRO) of aircrafts, military equipment, space crafts, etc. are getting more complex due to an increasing integration of electronic components and particularly printed circuit boards (PCBs). Especially with fast technological changes and challenges, new components are constantly being developed and their time for market availability shrinks and the PCBs can no longer be repaired and this is causing obsolescence.

The other part of the problem is to secure repair and maintenance for the future of the devices the necessary documentation on them is needed as well. A lot of times, the corresponding information explaining the function and structure of the device such as schematics or bill of materials are incomplete or missing.

Now, the Digitizer 2.0 can automatically reconstruct CAD data of unknown assemblies by a non-destructive electric analysis within a Condor Flying probe test system. This highly automated assembly analysis enables the automatic netlist extraction or – verification. This process is extremely fast and results can be retrieved within a few hours.

Also a variety other functions such as the components library or the innovative "Soft Landing" technique to scratch free touch of the pad are only some highlights. Also highly efficient methods for determining unknown component types and their values. The Digitizer 2.0 achieved to make it possible to penetrate insulating varnish layers. This means the PCB can be electrically analyzed now for the first time, which were previously inaccessible, because of special varnish layers which guard the PCB against weathering.

TECHNOLOGY FORUM (Wednesday 18th November at 11 am)

INPIKO research project:

In the Technology Forum, Olaf Rohrbacher, from Digitaltest will give a presentation titled: “Obsolescence management: automated recovery of CAD data with Digitizer 2.0 “. Following this presentation all interested visitors are cordially invited to the Digitaltest booth (Booth F85).

The INPIKO research project – Integrated Process Chain for Maintenance of Electronic Components – was supported by the BMWi and the ZIM funding program.

About Digitaltest

Digitaltest is a strong partner of the electronics industry and has more than 35 years of experience in development, implementation and support of automated test equipment (ATE) for electronic circuit boards. The complete product portfolio of the global company includes hardware technology, software to automate the production and evaluate the production process with its quality management software.

Quality and efficiency

Digitaltest solutions creates an efficient link between CAD, testing and production. This results in optimized production processes that are convincing in terms of quality as well as by increasing capacity and efficiency.

More than 2,000 systems worldwide

Digitaltest customized test systems are used and proven itself in all key industries. More than 2,000 installations have been installed in numerous leading companies in the electronic contract manufacturing services (EMS), automotive industry and in transportation, aerospace, telecommunications, medical and industrial technology, consumer electronics and many more.

360° solutions – from a single source

The range of services offered includes the development of innovative application-specific test procedures, implementation, training, service and support – or even the complete outsourcing of PCB tests – all relevant phases of the process. Regardless of which modules your personal package include – you get reliable high technology with superior long-term impairment.