Visitors are invited to experience our new applications in ICT, Functional and Flying Probe Test and technology-leading software tools. Equipment on exhibit includes Condor Flying Probe system - second generation, Sigma 300 In-Circuit Tester with a new migration tool and our state-of-the art software offerings-QMAN Quality Management Software and CLINK DTM.

New Condor Flying Prober capabilities:

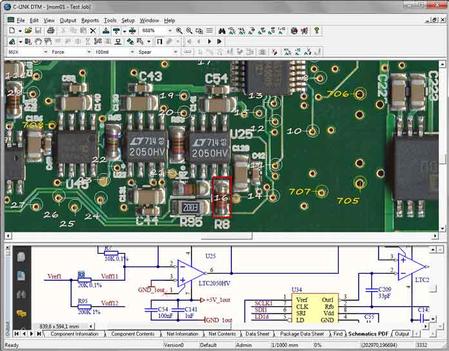

The test heads of the Condor flying probe test system can land on small SMT leads of components. C-LINK DTM has an improved Flying Probe algorithm. If a pad is accessible by more than one head the new calculation by C-LINK DTM will determine the head which guarantees the best and most reliable contact. With the latest C-LINK DTM software it is now possible to create very robust test programs in much shorter development time.

New Applications for C-LINK DTM Software:

- New Flexible Measurement Tool-allows for precise measurement between any two points on the UUT.

- New Importing Assembly File-provides graphical view when NO CAD data is available.

- New C-LINK Layout Viewers are often used at PCB inspection and PCB repair stations. When there is no CAD data available, C-LINK DTM can now import PCB assembly files and merge them with the board image to provide powerful graphical support for inspection and repair.

- The C-LINK Layout Viewer software now includes a new comprehensive COM interface to establish a bi-directional communication with external software.

- C-LINK can import a text file to exclude nets from nail assignment. This can be used to eliminate redundant tests (like ICT / Boundary Scan) which can reduce test program preparation time, test time and fixture costs.

- C-LINK can now communicate with PDF schematics to highlight components in the circuit diagram when the PDF has "searchable" labels. Each assembly variant can have its own schematics files. When a component is selected in C-LINK Layout View, it will also be highlighted in the circuit diagram. The communication with the PDF schematics facilitates the fixture and test program development.

Boundary Scan and Flying Prober Combination – A Powerful Test Solution

Combining the benefits of flying prober with boundary scan creates a powerful test solution. Digitaltest’s Condor flying prober permits functional tests using up to 1012 fixed probes accessing from the bottom side. The fixed probes can access the UUT using a simple magnetic probe bed or a sophisticated vacuum operated adaptor.

Digitaltest can integrate with any Boundary Scan platform.

At APEX we will show the Condor system with integrated Corelis Boundary-Scan (http://www.corelis.com).

Highlights include:

- Power On Test

- Functional Test including:

- Voltage Test

- Current Measurement

- Flash Programming

- Eprom programming

- Virtual Digital Pins

- On-Board programming

Learn how using Boundary-Scan will decrease test time dramatically and provide more and better test coverage of the UUT using a simple low-cost fixture.

New QMAN-Quality Management Software Tools

QMAN software can help assess the efficiency of the production process, optimize repair time, create reports and alert you when problems arise. Since its introduction in 1992 QMAN has helped process millions of boards for our customers.

Generic fault data collection from almost any test system, inspection and monitoring station.

- New Visual Inspection Station

- Cross-link between layout and schematics.

- Centralized SQL database that holds all board history

MTS300 Sigma : Migration Solution Life at the Show

The MTS300 Sigma from Digitaltest is designed to meet the demands of today's test systems; flexibility, high fault coverage and ease of programming. Sigma test systems provide analog and digital In-Circuit Test capabilities, Vectorless Testing, Functional Test, Boundary Scan and On-Board Programming. The Sigma system will be shown with a Z1800 fixture and converter to demonstrate how easy it is to migrate from legacy 1800s to the new Sigma technology. Digitaltest is helping many customers to save money as they move from legacy test equipment to Sigma by keeping their existing fixtures. Results include faster test times, better test coverage and more test capabilities. The MTS300 Sigma from Digitaltest is designed to meet the demands of today’s test systems with our CITE software.

Additional Services for our clients - Reverse Engineering

Digitaltest offers a Reverse Engineering Service to help clients recover the design of a board and to be able to repair and/or re-manufacture the PCB's again. Digitaltest developed a specific tool for reverse engineering named Digitizer. With the help of the Digitizer the board data is re-created and all the connectivity is discovered. A CAD file for the board can then be generated that has all the board components and nets and that can be used in repair and/or re-manufacture. Digitaltest can also provide clients with the board schematics.

As a strong partner for the electronic industry Digitaltest develops and manufactures automated test equipment (ATE) for electronic printed circuit boards (PCB), software for production automation and quality management systems.

Digitaltest has created innovative and often pioneering solutions that integrate CAD, test and production to optimize the entire manufacturing process. Digitaltest also offers extensive service and support options, up to complete outsourcing of your board testing requirements at any of our facilities all over the globe.

Digitaltest hardware and software is being used in key industries including aerospace, avionics, automotive, telecommunications, medical, industrial and consumer electronics and more. With over 1,650 installations around the world, Digitaltest is a trusted partner to the industry.

Corelis, Inc., a subsidiary of Electronic Warfare Associates, Inc., offers bus analysis tools, embedded test tools and the industry’s broadest line of JTAG/boundary-scan software and hardware products combining exceptional ease-of-use with advanced technical innovation and unmatched customer service. Corelis products are found globally in every industry developing or manufacturing electronic products.