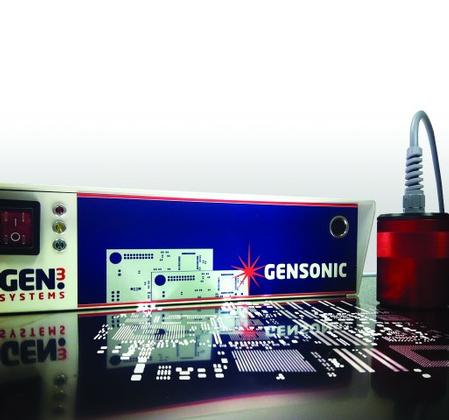

Gen3 Systems Limited, a specialist British manufacturer and distributor, today announced that they will exhibit at National Electronics Week (NEW) ADEC Expo South Africa, scheduled to take place March 11-12, 2014 at the Gallagher Convention Centre in Midrand, Johannesburg. Quamba Technologies, Gen3’s South African Distributor, will be exhibiting alongside Gen3 and will be displaying the European Product of the Year, the Gensonic Stencil Cleaning system.

The Gensonic Stencil Cleaning System, which received its award at productronica 2013, is a manually operated ultrasonic transducer unit for cleaning stencil apertures.

The Gensonic can be used either in conjunction with our Stencil Cleaning Centres or it is portable enough to be taken directly to the printer, thereby greatly reducing production downtime and printer resetting.

The key features of the Gensonic System are:

Safe and simple to use

No risk of stencil damage

Typical 3-minute cleaning cycle

Suitable for both stainless steel and plastic stencils

Cleans solder paste or SMD adhesives

Accepts both foils and framed stencils

Dr. Beverley Christian of Blackberry quoted in a technical paper titled ‘Cleanliness of Stencils and Cleaned Misprint Circuit Boards – Précis,’ “Solder pastes, especially lead-free pastes tend to become compacted and trap particles, blocking fine apertures and deforming aperture corners. Using proven industry cleaning solution and the Gensonic ultra-sonic transducer directly on the stencil, even the smallest tightest pitch apertures can be cleared and perfectly cleaned. Many users have found that their conventional cleaning systems are 80-90% effective, leaving the smallest, most sensitive apertures partially occluded. Using the Gensonic these apertures can be cleared and renewed. This system is effective as a localised cleaner, applied during the print cycle while the stencil is in the printer, preventing expensive and time-consuming shutdowns required to clean problem apertures.”

With more than 5,000 users worldwide, the Gensonic is a system that should be on everyone’s production line.

Also available in Gen3’s manufactured product line is the Ionic Contamination Systems, also known as the CM Series, Dip and Spray Coating Systems, Wizard Thermal Profiling, SIR and CAF Testing Systems, Solderability Testing, Solder Dross Recovery and Solder Paste Inspection.

For more information about Gen3 Systems, visit www.gen3systems.com.

Gen3 Systems is a specialist manufacturer of test and measurement equipment used to help predict reliability of electronic circuits and systems in the field. In addition, the company designs and manufactures dip and spray coating process equipment in both in-line and bench-top formats. Gen3 is a specialist distributor for several leading equipment manufacturers including, ACE, DIMA, FineTech, MBTech, MEK, Optilia and, most recently, Global Distributor for Aprotec Instrumentation, Solder Paste Inspection (SPI) systems.

Gen3 Systems also provides training, equipment and expertise for manufacturers requiring assessment of their electronic products’ reliability. The company also operates a test service and assists with standards development via both the IPC and IEC. Gen3 Systems operates from premises near Farnborough Business Park, on the M3 corridor and just 30 minutes from London’s Heathrow Airport.

Quamba Technologies are located in Johannesburg, South Africa. They are a supplier of production equipment for electronics manufacturing. They supply products from leading global manufacturers, providing excellent local technical and after-sales support.

For more information about, Quamba Technologies visit, www.quamba.co.za.