In this newsletter we describe a new method of testing the seal and adhesive quality of a lid encapsulated devices.

Typically this test is done by stud pull and gluing the lid and base of the device to two blocks of metal with screw holes in them that are used to apply the pull load. The disadvantages of this include;

- The cost of the disposable metal block/studs and adhesives.

- Handling of adhesives in the production environment with the risk of clean room contamination together with operator and equipment safety.

- Imprecise alignment of the studs to the device.

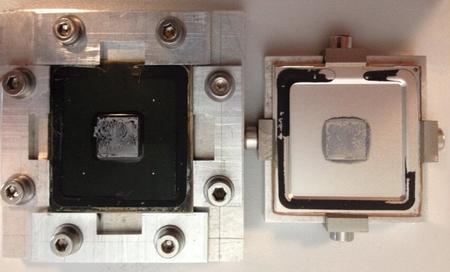

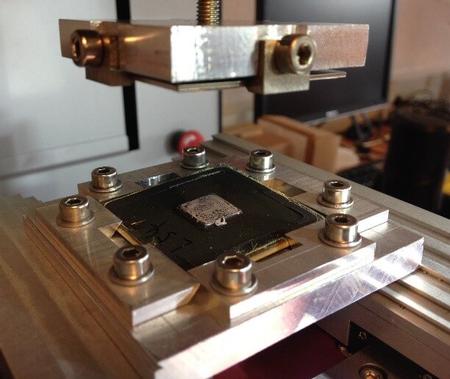

The new XYZTEC mechanical grip method consists of reusable parts that are accurately aligned the test load to the device. They can be quick release and in many cases handle a range of similar devices.

The lid and base of the device are gripped along their edges by side clamps.

The grippers can be screw fixed as is this example or quick release with a single lever operation. When the gap between the lid and its base is very small some sample preparation will probably be required. In such cases a bench mounted preparation jig can be provided.

The bond can also easily be tested at elevated temperature by mounting either the lid clamp or base clamp onto a heated platform. See our extensive range of work holders.

Learn more about the Condor Sigma

If you are interested in a live demonstration of the Condor Sigma on your sample or perhaps for more bond testing inspiration, contact us today! If you like our newsletter, feel free to share it with a friend or colleague.

About XYZTEC

XYZTEC manufactures and supports a complete range of bond test equipment for the printed circuit board assembly, semiconductor and other industries. The company was founded in 2000 and has seven direct offices around the world, with headquarters in Panningen, The Netherlands.